ISO Certified | Comply with Radiation Safety Regulation

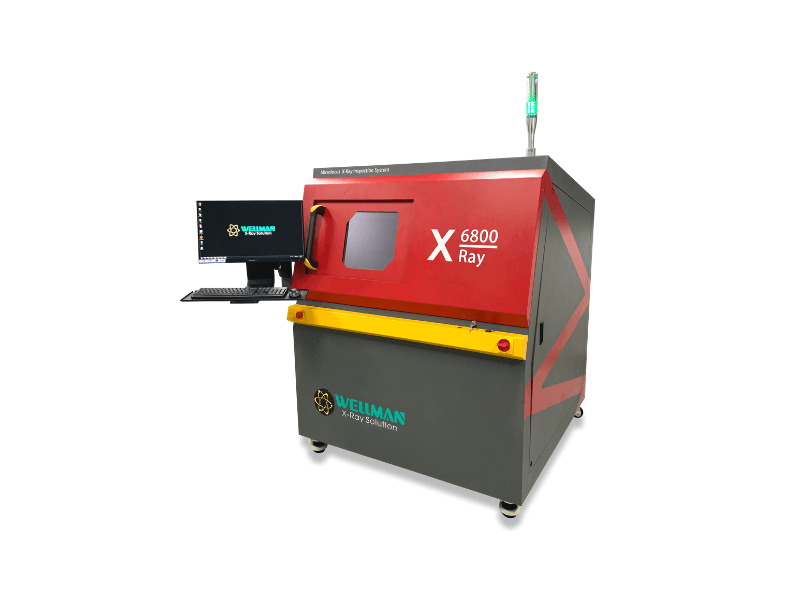

X-Ray Inspection System

- 90 - 130KV Sealed Type

- Ultra Fast X-Ray Imaging

- Support Parts Size up to 20"

- Radiation Safety Certification

- Maintenance Free

ISO Certified | Comply with Radiation Safety Regulation

X-Ray Parts Counter

- Automatic Parts Recognition

- Fast Parts Counting up to 7s

- Support Max Reel Size 17"

- MES/ERP System Support

- Maintenance Free

ISO Certified | Comply with Radiation Safety Regulation

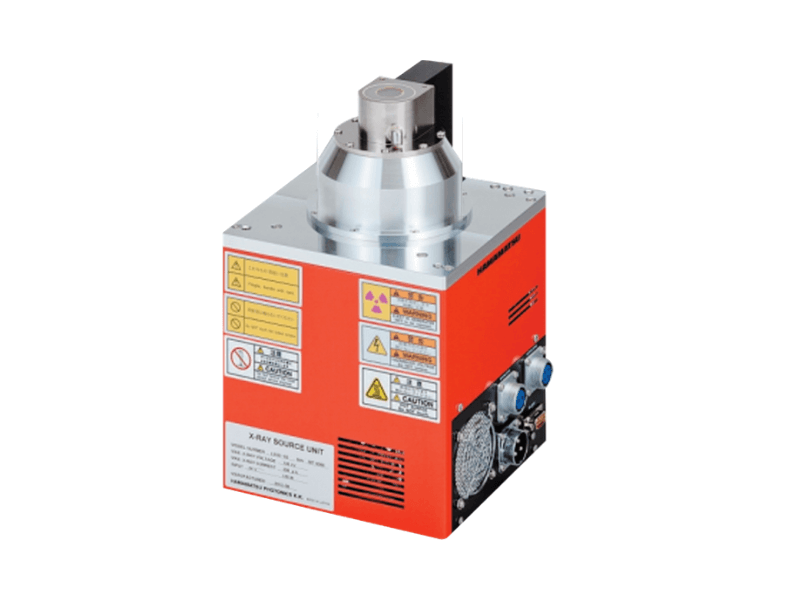

X-Ray Tube Parts

- 90 - 130KV Sealed Type

- Focal Spot Up to 5μm

- Easy to Use

- Maintenance Free

- Wide Range Application

Our Product

The X-ray inspection system is essential in ensuring product quality and safety, Wellman have developed X-ray inspection system and X-ray component counter machine with innovative and cutting-edge technologies that provide

excellent inspection accuracy, speed, and efficiency in the X-ray inspection process.

X-ray Inspection System

X-Ray Counter System

Inline X-ray Inspection

SMD Tower

X-ray Tube and Detector

Labeling Machine

Senser Type Smart Reel Rack

The Reliable Choice for Quality Assurance

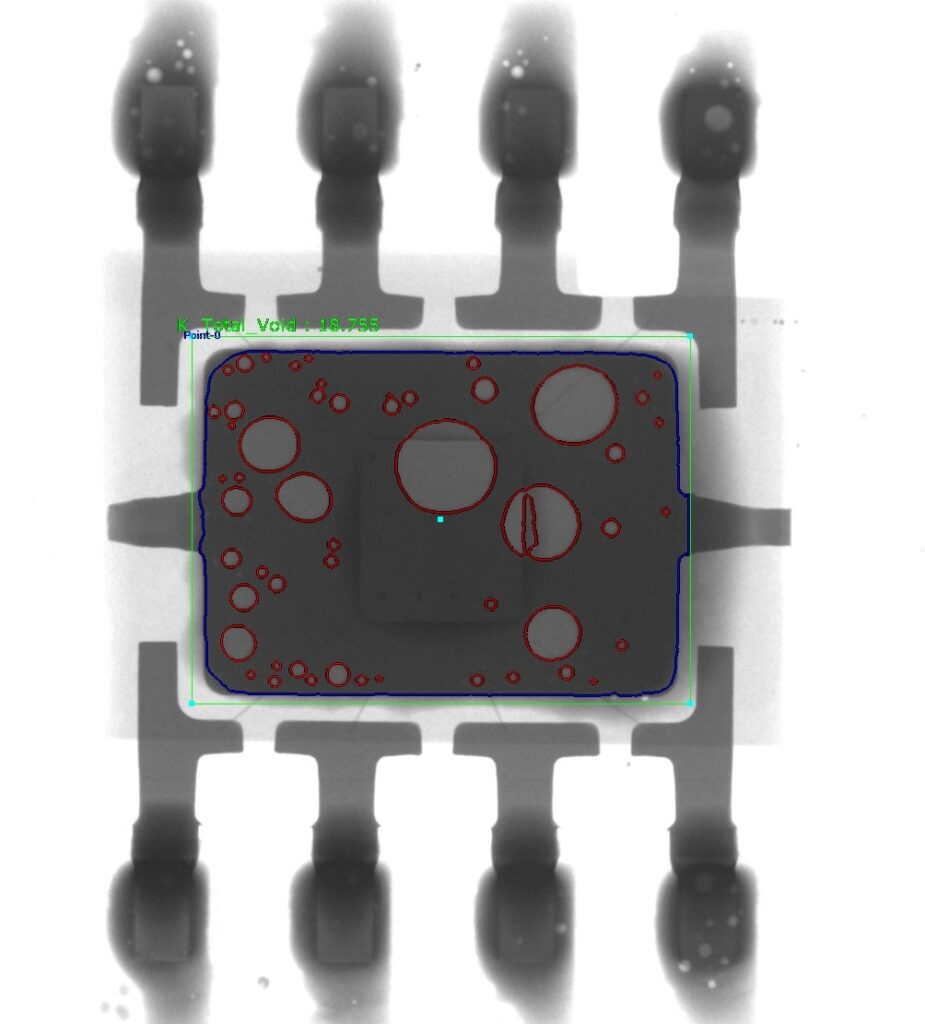

X-ray inspection technology provides a non-destructive and non-invasive method for detecting internal defects and ensuring product quality. X-ray inspection equipment can detect a wide range of defects, including cracks, voids, foreign material, and other types of manufacturing defects that may not be visible to the naked eye. With the ability to detect these defects early in the production process, X-ray inspection can help ensure that products meet the highest standards of quality and safety.

Why Choose Wellman

Wellman is committed to developing and delivering innovative and reliable industrial X-ray inspection services to customers worldwide. Our team of experts has the knowledge and experience to develop customized solutions that meet the specific needs of our customers, ensuring optimal performance and efficiency.

Quick Response

We understand the importance of timely support and quick response times. Our customer service team is available 24/7 to provide expert technical support, troubleshooting, and remote assistance.

Quality Guarantee

Quality is at the heart of everything we do at Wellman. We are committed to providing our customers with the most reliable, accurate, and efficient X-ray inspection solutions on the market.

Customer Service

We pride ourselves on our commitment to customer service. We work closely with our customers to understand their needs and develop customized solutions that meet their specific requirements.

Served Industries

At Wellman, we specialize in providing cutting-edge x-ray inspection systems to a wide range of industries. Our advanced X-ray technology and experienced team allow us to deliver accurate, efficient, and cost-effective solutions for a variety of applications

Aerospace

Semicon

Batteries

Automotive

Consumer Products

Welding

Electric Power

Science & Research

Trusted Clients

What Our Customer Say

Blog & News

Hamamatsu Tubes – The Key to Precision Inspection

Foreword In the world of electronics manufacturing, the performance of X-ray inspection equipment directly impacts product quality and customer trust. As the “heart” of every X-ray system, the choice of X-ray tube is critical. At

How Wellman X6800 Enables Solder Filling Inspection?

Intro In the world of electronic manufacturing, ensuring the quality of through-hole solder joints is crucial for product reliability. Traditional inspection methods often struggle to reveal internal solder filling conditions without destructive testing. This is

X-Ray Detectors: Selection & Applications Guide

Introduction In industrial nondestructive testing (NDT), the precision of X-ray technology directly determines the success of quality control. As the “eyes” of an X-ray imaging system, detectors play a pivotal role in defining image clarity,

Frequently Asked Questions

What is X-ray inspection?

X-ray inspection is a non-destructive method of detecting defects or foreign objects in products or packaging by passing X-rays through the item being inspected and analyzing the resulting image.

What products can be inspected using X-ray inspection systems?

X-ray inspection systems can be used to inspect a wide range of products, including food and beverage packaging, pharmaceuticals, electronics, and automotive parts.

How does X-ray inspection work?

X-ray inspection works by passing X-rays through the product or package being inspected. The X-rays are absorbed differently by different materials, allowing the system to detect defects, foreign objects, or other anomalies.

What are the benefits of X-ray inspection?

X-ray inspection can help ensure product quality and safety by detecting defects, foreign objects, or other issues that could affect product performance or consumer health. It can also help reduce waste and improve production efficiency by identifying and removing defective products from the production line.

Can X-ray inspection systems be customized to fit specific production lines?

Yes, X-ray inspection systems can be customized to fit the specific needs of different production lines, including the size and shape of products being inspected.

Are X-ray inspection systems expensive?

The cost of X-ray inspection systems can vary depending on the complexity of the system and the specific needs of the production line. However, the benefits of increased product quality and safety, reduced waste, and improved efficiency can make them a worthwhile investment for many companies.